The finishing of heating structures should incorporate building materials like refractory concrete, whose applications and advantages are rooted in its exceptional resistance to extreme temperatures.

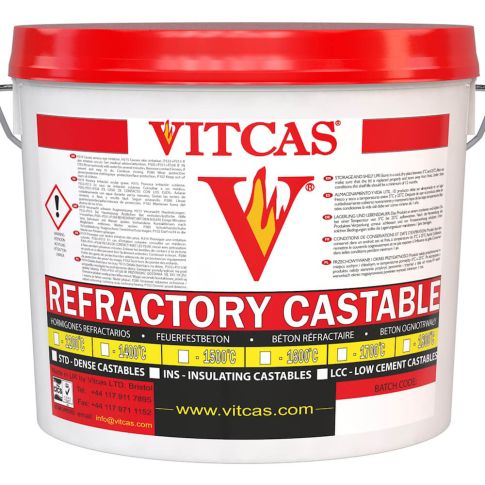

Refractory concrete is a building material with unique properties. Available from Vitcas, it stands out for its resistance not only to high temperatures but also to various mechanical impacts. When exposed to an open flame, refractory concretes remain flexible, resisting cracking and crumbling. This makes them ideal for constructing heating devices such as stoves, fireplaces, boilers, grills, and smokers. Vitcas offers refractory products, including fireclay and low-cement concretes. Insulating concrete with low density and thermal conductivity is also recommended, though it tends to wear down more easily.

What is Refractory Concrete and Why Use It?

Refractory concrete serves as an alternative to traditional construction concrete, specifically designed for high-temperature applications. The Vitcas fireclay refractory concrete is manufactured to BS EN ISO 9001:2015 standards. It’s a binding material that not only bonds surfaces but also serves as a lining for various heating devices. Low-cement refractory concretes, with reduced alumina content, are suitable for extreme thermal conditions and can be used to finish areas like steel ladle interiors, furnace hearth blocks, or mixing ladle throats for iron.

Further Reading:

The use of chamotte concrete in heating structures

Replacing the fireplace door seal is not difficult

Refractory concrete is an essential building material for creating high-temperature structures. It comes in various types with different applications and durability levels.